JOULE-THOMSON (JT) CRYOGENIC COOLING

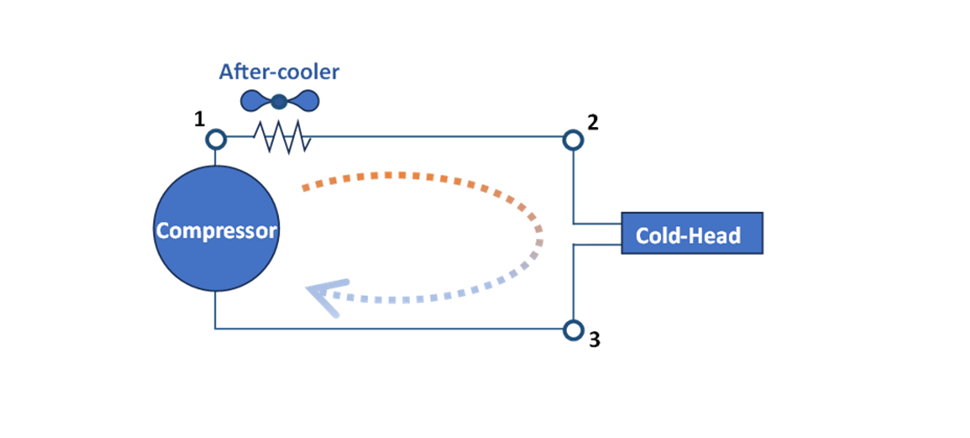

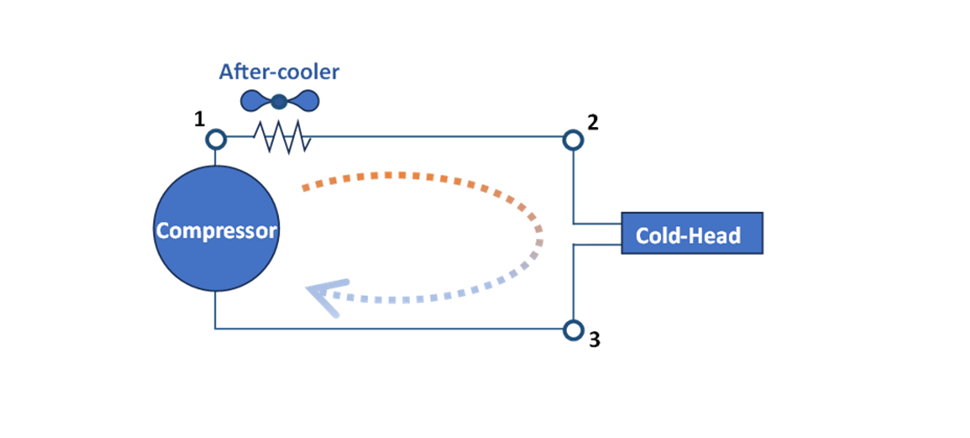

Joule-Thomson cryocoolers, also known as Linde-Hampson cryocoolers, are based on the principle of Joule-Thomson expansion. A schematic view of a JT cryocooler is shown in Figure 1. These cryocoolers function through the continuous flow of refrigerant, expanding from high pressure to low pressure at the cold-head. This expansion drops the refrigerant temperature to the required cryogenic level. The refrigerant is then recompressed to high pressure, passing through an after-cooler to bring it back to ambient temperature. JT cryogenic systems enable the use of lengthy connecting lines between the compressor and cold head. Our

previous research demonstrated the successful operation of an IR camera with a JT cryocooler, placing the compressor 25 meters away from the camera. Additionally, these connecting lines can be flexible, allowing for on-gimbal positioning of the cold-head while keeping the compressor off-gimbal. A key advantage of JT cold-heads is their lack of moving parts, eliminating vibration and noise emissions. This design results in high reliability, and longevity, and negates the need for regular maintenance. Moreover, JT cold-heads don’t emit heat as the refrigerant both enters and exits the cold-head at ambient temperatures.

Open cycle JT cryocoolers:

Open-cycle JT cryocoolers are driven by pressure vessels, instead of compressors. Usually, the vessel contains a high-pressure refrigerant (a few hundred bars), which is discharged through the JT cold-head on demand. This allows to obtain cooling without any power consumption on-site because the work is invested in pressurizing the refrigerant at the factory. Open-cycle JT cryocoolers often operate with pure refrigerants, which are determined mainly by the required cooling temperature. This is the only technology that allows extremely fast cool-down of a few seconds only. In previous work (

20082 ,

20143 ) we investigated fast cool-down of various open cycle JT cryocoolers. The major drawback of open-cycle systems is their limited operating time. When the vessel is empty, the cooling effect stops.

Mixed-Refrigerants

Mixed refrigerants aim to replace pure refrigerants, to allow lower operating pressures, and therefore, closing the cycle with compressors (instead of pressure vessels), and obtaining a continuous operation (24/7). The mixture composition is determined to comply with the cooling requirements: cooling temperature, cooling power, cold-temperature stability, refrigerant flammability, environmental restrictions, and more. We have much experience in researching and developing mixed refrigerants for different JT cryocoolers (

2012a4,

2012b5,

2014a6,

2014b7,

2014c8,

2016a9,

2016b10).

Advantages of JT cryogenic cooling systems

-

Performance:

cooling temperatures: 70°C down to -200°C, cooling power: from tens of milli-Watts to tens of kilo-Watts. There isn’t a limit for the cooling capacity, because it is a function of the refrigerant’s flow rate, which can be determined to comply with any cooling power demand.

-

Cold-Head:

small dimensions, absence of moving parts (no vibration and no noise), no heat emission, flexible design to comply with the customer's needs.

-

Refrigerant:

pure or mixed, possibility to be optimized for high efficiency, flammability requirements, complying with environmental restrictions.

-

Compressor:

commercial oil-lubricated, self-made oil-free, possibility to redundancy.

-

System:

long distance between compressor and cold head (tens of meters), flexible connecting tubes between compressor and cold head. The absence of moving parts in the cold head makes the compressor the main component that might need maintenance. Since the compressor can be located away from the cooled object, maintenance is simple and fast.